Ductile Ni - Resist Iron

When SG iron is alloyed with Nickel, a nodular iron with a stable austenitic structure is produced. This material has superior oxidation and elongation resistance up to the temperature of 925°C.

Ni-Resist Irons are widely used in exhaust and turbocharger systems of the automobiles, and gas turbines where temperature changes in a range between 500°C and 1050°C. Ni-Resist irons are preferred in these applications because of their outstanding characteristics such as ductility, high strength, and low thermal expansion coefficiency. These properties provide high resistance against these kinds of severe thermal shocks.

The physical properties of the material vary based on the nickel content in the SG iron alloy’s composition and the operating temperatures.

Features

Features

-

Economic: Ni-Resist casting irons offer significant price advantages compared to stainless steel castings. Ni-Resist casting irons are lighter materials than stainless steel castings. They can be cast almost in their final shape.

-

High Machinability: The machinability of Ni-Resist iron is higher than that of stainless steel. Moreover, Ni-Resist iron castings have lower machining allowances than stainless steel.

-

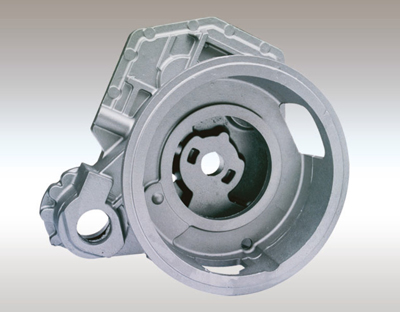

Castability: Just like Grey Iron and SG Iron, Ni-Resist iron castings also offer all the advantages of Iron Castings in terms of design. Complicated geometries and challenging designs can be achieved, and an excellent surface finish can be performed.

Manufactured Grades

Properties

Features

- TENSILE STRENGTH (Rm) 380: 500 N /mm2

- BRINELL HARDNESS 130: 170 HB

- ELONGATION (A) 10: 20%

- MODULUS OF ELACITY (E) 130 to 150 kN / mm2

- PROOF STRESS (Rp 0,2) 210: 270 N /mm2

Chemical Composition

Please kindly click on below PDF document to see detailed chemical composition.