MATERIAL TESTINGS

NON - DESTRUCTIVE TESTINGS (NDT)

VISUAL INSPECTION (VT)

The main purpose of this original testing method is to detect surface defects such as corrosion, misalignment of parts, physical damage and cracks by using visual observation of the surface. It is the most effective nondestructive testing style.

LIQUID PENETRANT TESTING (PT)

Liquid penetrant testing, also named as dye penetrant test, discovers surface cracks and pores by practising capillary forces in order to make them visible. Several surface breaking flaws such as porosity, laps, and cracks can be detected with this method.

MAGNETIC PARTICLE TESTING (MT)

This test method is used to detect discontinuities and defects located on surfaces and in shallow subsurfaces up to 2 mm deep, which is hard to see by naked eye.

It is conducted by using ferromagnetic particles under magnetic fields on inspected areas of the tested item. The purpose is to discover the defect by presence of a flux leakage field. These applied ferromagnetic particles are suspended in a liquid or in air.

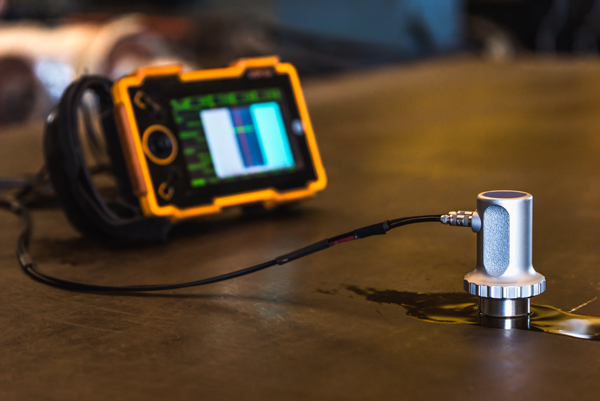

ULTRASONIC TESTING (UT)

The ultrasonic inspection is crucial test for safety relevant components. Invisible problems and covered inhomogenities can be discovered and localized by applying this test. It also provides wall thickness measurements beside flaw detections.

RADIOGRAPHIC TESTING (RT)

This test uses either gamma rays or X-rays to view the interior of a component. It is utilized to discover flaws in pressure vessels and valves in petrochemical industry. It is also exercised in inspecting weld repairs.

RT is offering several advantages compared to other non-destructive techniques. These are;

- does not require too much surface preparation,

- easy to use in the fields and at elevated positions thanks to its portability,

- can be used on variety of materials,

- Collected data can be saved for later analysis.

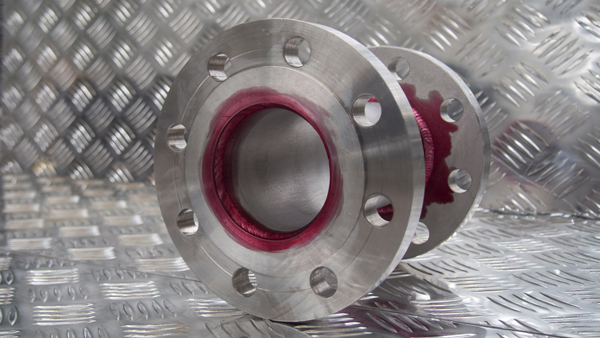

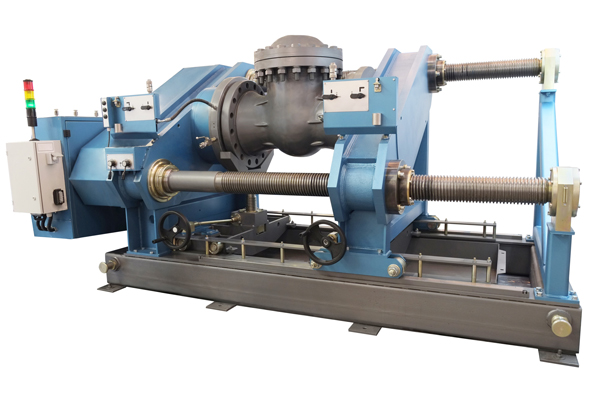

HYDROSTATIC TESTING

By applying this method, coherence of vessels is tested under pressure for discovering leaks, proving the strength and validating performance.

Hydrostatic Testing is one of non-destructive tests, however; if a failure occurs and the piece does not meet the durability or performance specifications, the vessel may become unusable.

When / after applying this test, there are several indicators show inadequate vessel quality. These are;

- leakage through the product and malformation,

- a decrease in the applied pressure,

- bulging or distortion in the product

We want to make our websites more user-friendly and continuously improve them. If you continue to use the websites, you agree to the use of cookies. OK For further information, please refer to our cookie policy...