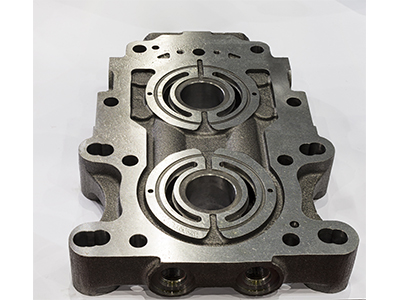

Grey Cast Iron

As the oldest cast iron, Grey Iron is the most common type. That is why people use “cast iron” and “grey iron” terms interchangeably. Grey iron is widely preferred in engineering applications requiring no high strength or no ductility. Also, it can be used in sliding surface applications because of its unique strength.

Manufactured Grades

For detailed grades, please see the table at bottom of this page…

Properties

Features

-

COST: Grey Iron has the lowest production cost among all other cast irons.

-

EASY TO CAST: Grey Iron has the lowest melting point among all ferrous metals, and it shows high fluidity in the molten state.

-

EXCELLENT BEARING PROPERTIES: The free graphite in its structure provides lubrication. Therefore, it can be used in hydraulic pistons, machine tool beds, etc..

-

EXCELLENT MACHINABILITY: Free graphite interrupts the continuity in the matrix structure of the material and facilitates the formation of small chips in the material, thus, improves the machinability.

-

SUPERIOR DAMPING PROPERTIES

-

SUPERIOR WEAR CHARACTERISTICS

-

METALLURGY: Grey iron or Cast iron has graphite content in the form of flakes, which interrupt the matrix structure. Thus, it has very low, almost no, ductility, and relatively low strength.

For detailed features, please see the table at bottom of this page…

Detailed Material Properties Table

Please kindly click on below PDF document to see detailed material properties table.