Aluminum Casting

Molten aluminum is formed by pouring it into moulds that were already designed and produced according to the intended geometry of the final product. Usually, three methods are used in aluminum casting: die casting, sand casting, and permanent mould casting.

Thanks to metallurgical processes, various casting alloys can now be used for our final application. Based on various parameters and their composition, casting alloys have different properties such as machinability, weldability, hardness, corrosion resistance, strength, and heat treatment properties.

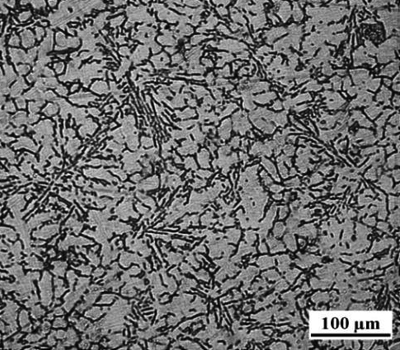

Some aluminum alloys are subjected to the heat treatment process to improve their properties to make them available for specific manufacturing applications. For instance, we can obtain an evenly distributed molecular microstructure in a solid cast aluminum material by heating the material to a certain degree. When we apply an instant cooling to the material, the microstructure of the material remains the same, thus, we obtain the intended properties.

Aluminum casting, which has an aesthetic appearance, also offers the advantage of availability for various coating and finishing processes. Besides, the coating process may enhance the benefits of finishing.

Features & Applications

Features

- Perfect chemical resistance and corrosion resistance

- High specific strength (strength-to-mass ratio)

- Good electrical and thermal conductivity

- High machinability

- Reflecting light and heat

Applications

- Auto parts

- Cooking Utensils

- Aircraft parts

- Medical Devices

- Electronic Enclosures

- Handles & Knobs

- Optical Reflectors

- Lighting Fixtures

- Engine parts

Machining Options

Other Information

Advantages

Transportation Industry: As a light, strong, and easily machineable material, aluminum is a widely preferred material in transportation applications. It is an ideal material to be used in land vehicles, air crafts, rail vehicles, and vessels. Aluminum engines are also used to achieve fuel efficiency in automobiles and trucks. Since it is a lightweight material, it provides fuel savings and reduced emissions.

Construction Industry: Aluminum is a preferred material also in the construction industry since it is corrosion resistant and provides economic solutions. Aluminum products are not only used in new construction projects but also renovation works. Moreover, it is an ideal construction material in regions susceptible to earthquakes because of their advantages in terms of strength and lightweight. Also, it is widely used in lighting devices due to its high reflecting capacity.

Automotive Industry: In a traffic accident, the vehicle’s frame, which is usually made from aluminum alloys, absorbs most of the impact that the vehicle is exposed to.

Aerospace Industry: Aluminum alloys, which have high strength values, are used in the air vehicles to resist against extreme pressures and external stresses being exposed to at high altitude flights. Aluminum wafer panels used in the body of the aircraft does not allow thermal transfer between the air and inside of the plane. Moreover, aluminum or aluminum composite materials are used for most of the internal fittings of airplanes such as seats, overhead lockers, armrests, etc. because they are light. This reduces the fuel consumption and emission of the aircraft, as well as, enabling to increase the payload.

Packaging and Food Processing Industry: Since aluminum is a non-toxic material, it can be safely used in the kitchen. For instance, non-acidic food can be wrapped using aluminum foil or aluminum cookware can be safely used to cook food. Since it is a lightweight material, aluminum kitchenware is easy to handle, and it can be quickly heated compared to stainless steel and cast iron.

Power Transmission Lines: As a safe conductor, aluminum wires can be safely used in thin wiring works and electrical home appliances such as bulbs and communication cables. Also, aluminum wires are used in the high-voltage transmission and power distribution lines over long distances.

Manufactured Alloys / Grades

Please kindly click on below PDF document to see detailed material properties table.